Kerb Stones are used to marking the boundary of the pavers and provide a fixed end. It is an essential addition to a road, cycleway or footpath. It has several uses, with its main purpose being to neatly create separation and visual delineation of walkways and other trafficked areas. There are mainly three different types of kerb based on their manufacturing process.

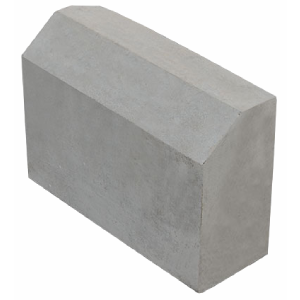

Hydraulic Press Kerbs:

This type of kerb is made with a manual process in hydraulic machinery, It is the mostly used kerb stone among all other as it is the cheapest one and easy to install at the site. so it is maximumly used in R&B works in Government Projects.

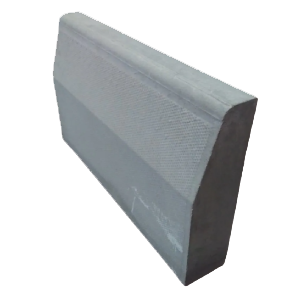

Rubber Mould Kerbs:

These Kerbs are made similarly to rubber mould paver blocks, in which one mould is required to produce one Kerb Stone, so it is quite costly compared to hydraulic. These kerbs have a Smooth surface finish with higher Strength. It is mostly used in residential, Commercial and Private Projects.

Vacum wet Press Kerbs:

This is the latest technology Product in which vacuum process and heavy machinery are used for manufacturing which is fully automatic and this kerbs provides high Bending strength and have a unique finished surface which gives the aesthetic beauty in projects like Special category works, Airports, Ports, Premium Infrastructure Projects, Buildings as well as many others Works.